All-rounder

ARS 2000 FS – our all-rounder

for the right DRIVE of your application

Highest performance and dynamics

High precision for NC applications

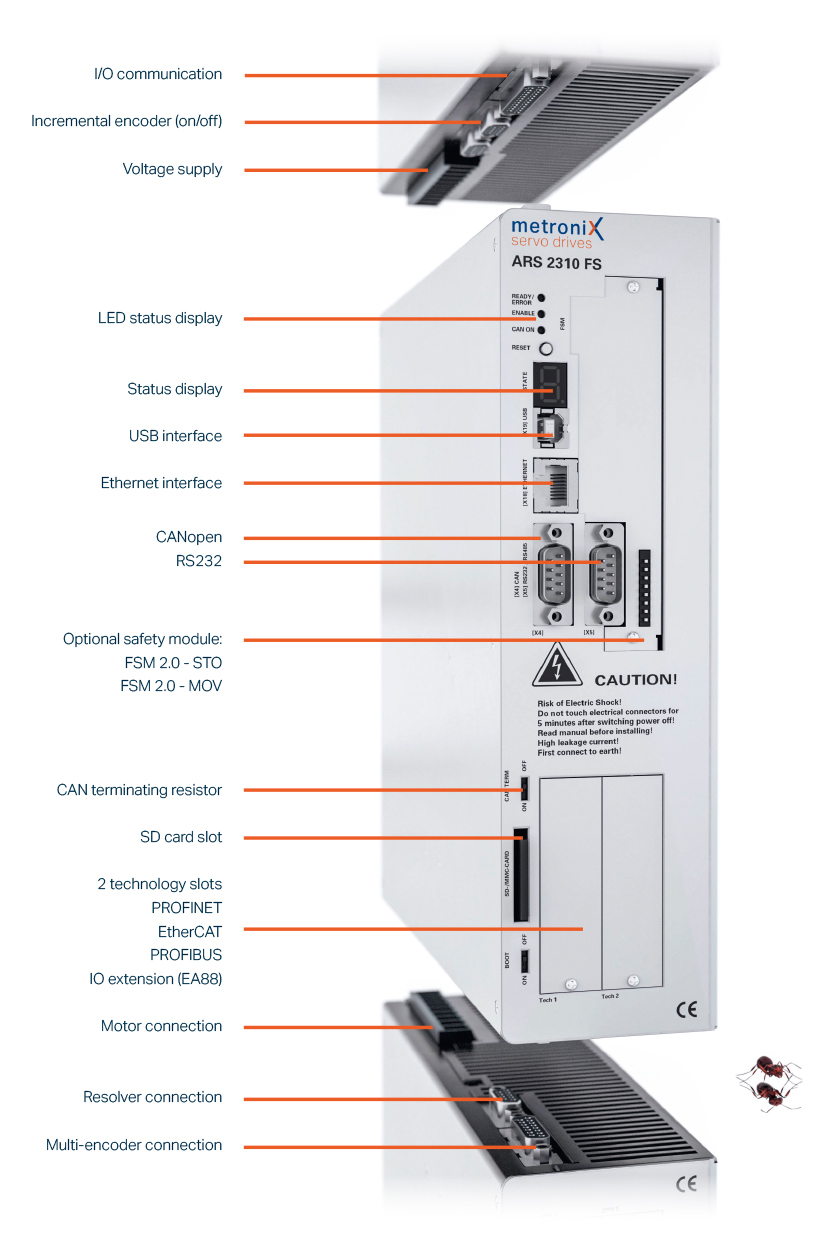

USB and Ethernet interface

On-board CANopen interface

EtherCAT and PROFINET

Integrated universal encoder evaluation

High-resolution SICK incremental encoders

High-resolution Heidenhain incremental encoders

Parameterisable notch filters

Jerk-limited or time-optimal positioning

Point-to-point positioning

Speed and angle synchronisation

Encoder emulation and pulse direction interface

Various methods

Support of multiple cam drives

Position trigger and rotor position trigger

Technology functions

on board

Numerous integrated software functions make the ARS 2000 FS servo drives real all-rounders in drive technology.

The ARS 2000 FS servo drives not only support numerous motor types and all common position encoders directly, but also can be adapted very flexible to a variety of applications via simple parameterisation of the integrated technology functions. The high-precise evaluation of external signals in the drive allows shortest possible cycle times.

Positioning

Whether linear, jerk-limited or torque-limited: With the integrated positioning control every motion task can be easily realised.

Path program / Linking

All 256 positioning sets can be linked to solve complex positioning tasks without external control system. Furthermore, digital inputs allow situation-related branching.

Flying saw

By integrating a „flying saw“ into the drive, not only short cycle times, but also extremely high accuracies can be reached.

Electronic gear/ Synchronisation

The position-synchronous or speed- synchronous motion of various drives with variable gear ratios can be quickly parameterised via the software assistant

CAM disk

Together with the integrated virtual master and with the synchronization the electronic cam can be used to coordinate several drives.

Linear motors

Special procedures for the determination of the commutation position and corresponding monitoring functions allow the operation of linear motors without commutation information.

Rotary table

For rotary table applications, several rotary axis modes are available. These can be combined with the cam disk and with the electronic gear.

Switching cams

Position trigger, rotor position trigger and switching cams in connection with the cam disk can be easily parametrised and connected to digital outputs.

Connectivity-Optionen

ARS ready for IoT

CANopen

The ARS 2000 FS servo drives always have on board the field bus system CANopen with the drive profile CiA 402. With the operation modes Profile Torque Mode, Profile Velocity Mode, Profile Position Mode, Homing Mode and Interpolated Position Mode the servo drive can be used in a variety of different applications. Several hundred parameters allow the complete parameterisation of the servo drive via CANopen.

Ethernet

The Ethernet interface also is on board and, via a UDP/IP connection, for example can be used for remote maintenance or as fieldbus connection. Here, the transmission of set points and actual values, an error analysis, loading and saving of parameter sets, the adjustment of single parameters and the display of values via the oscilloscope function can be realised.

EtherCAT

A plug-in module provides the user with the Ethernet-based fieldbus system EtherCAT. With the application protocol CoE (CANopen over EtherCAT) all operation modes and parameters of CANopen can be used also under EtherCAT. In multi-axis applications in the operation mode „Cyclic synchronous position“ in connection with Distributed Clocks (DC) highly synchronous movements can be reached even with high cycle times, as the servo drives run exactly synchronous with the external clock.

PROFINET

The Ethernet-based fieldbus system PROFINET also is available to the user as a plug-in module. Based on PROFIdrive the Metronix-specific application profile enables easy access to all functions of the servo drive. Ready-made function blocks and a sample project make the integration of the ARS 2000 FS into the control system a real piece of cake. Further, the plain text display of error messages in the control system simplifies the first set up significantly so that the machine is ready for use more quickly.

PROFIBUS

Even though in new systems mainly PROFINET is used in the meantime, a PROFIBUS plug-in module will be available further on. As well as for PROFINET the Metronix-specific application profile enables easy access to all functions of the servo drive. Here, too, ready-made function blocks and a sample project make it easy to integrate the ARS 2000 FS into the control system.

Encoder interfaces

EnDat 2.1 und 2.2

Heidenhain encoders with EnDat interface have a serial communication channel that is used for the communication between the servo drive and the encoder. Via this channel all relevant information is read out of the electronic nameplate of the encoder. This avoids a cumbersome manual parameterisation. If the used encoder also has an EEPROM, the motor information can be saved in the encoder so that the motor can be connected directly to another servo drive. The ARS 2000 FS supports EnDat 2.1 as well as EnDat 2.2 encoders, each as singleturn and multi-turn encoder.

HIPERFACE®

As well as the Heidenhain encoders, the HIPERFACE encoders have a serial communication channel that is used for the communication between the servo drive and the encoder. Here again all relevant information is read out of the encoder and motor information can be saved in the encoder. All common HIPERFACE single-turn and multi-turn encoders are supported..

HIPERFACE DSL®

The single-cable technique HIPERFACE DSL® transmits the digitalized encoder signal via the motor cable. Thus, a minimum of connecting lines between servo drive and motor is required. Of course, all features of the HIPERFACE encoders (electronic nameplate, information saving in the encoder) are also available in the HIPERFACE DSL® encoder.

Analogue and digital incremental encoders

The universal encoder interface supports a variety of different encoders. 1Vss signals are supported as well as digital track signals including homing tracks and index pulse. In addition to commutation, digital Hall signals can be evaluated and the determination of an error signal can be activated. One of the encoder inputs may also be used as pulse direction input or as forward-backward counting input.

Resolver

Of course, the ARS 2000 also supports the resolver as a robust and costeffective position encoder. Due to the outstanding high-quality resolver evaluation, the ARS 2000 FS together with a resolver can even be used in applications that normally would require a high-order encoder.

Safety

Scalability for your safety

The integrated safety technology is following the principle of scalability, too and can be adapted to suit any of your requirements. The basic safety function “Safe Torque Off (STO)” can be reached with the module “FSM 2.0 – STO”. Safety functions for rotational speed monitoring such as Safety Limited Speed (SLS) or Safe Operating Stop (SOS) are available via the module “FSM 2.0 – MOV”.

Functions

for safe sequences

STO - Safe Torque Off

Disconnection of the energy supply to the drive according to EN 61800- 5-2. This safety function ensures that the drive is unable to deliver energy.

SS1 - Safe Stop 1

The drive is braked self-sufficiently to idle within a defined time using a defined slowdown ramp and then the energy supply is switched off safely. All three versions described in the standard are supported.

SOS - Safe Operating Stop

This safety function is used when the motor position or the axis position has to be kept active and must be monitored safely.

SS2 - Safe Stop 2

The drive is braked self-sufficiently to idle within a defined time using a defined slowdown ramp. After the defined time has elapsed, SOS is triggered (Safe Operating Stop). All three states described in the standard are supported.

SLS - Safely Limited Speed

This safety function prevents the motor from exceeding a specified speed limit.

SSR - Safe Speed Range

This safety function is used when the speed of the drive has to remain within specified limit values.

SBC - Safe Brake Control

This safety function delivers a safe output signal to activate external motor brakes. This prevents an uncontrolled movement in the torque-free state. It is also possible to activate an external holding brake with integrated power electronics via safe outputs.

SSM - Safe Speed Monitor

This safety function monitors the speed of the drive within specified limit values. If these limits are violated (exceed or fall below) a safety-oriented signal output is triggered.

SDI - Safe Direction

This saftey function ensures that the drive can only move in the defined direction.

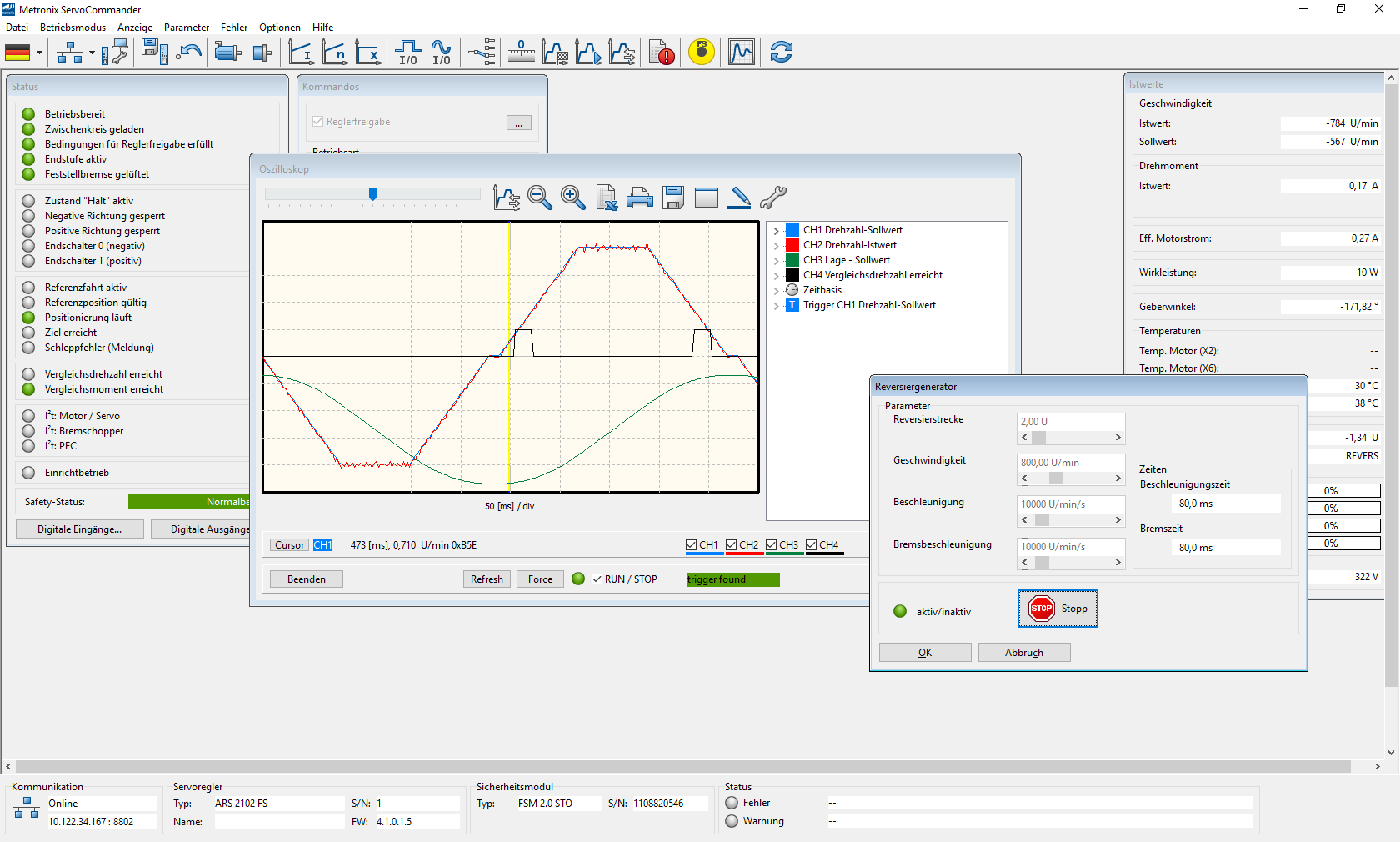

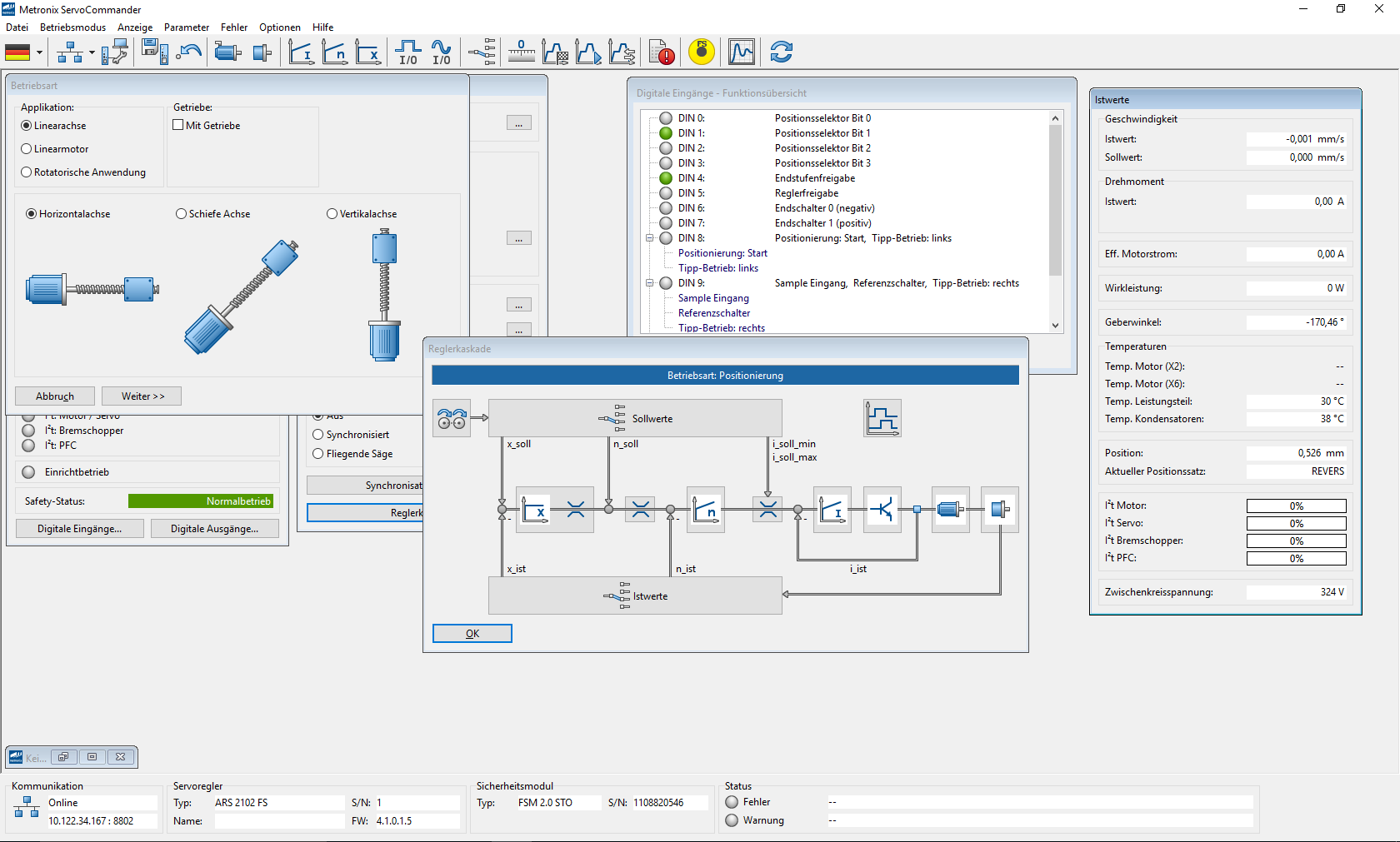

Visualisation in detail

The setup software Metronix ServoCommander® allows a quick and easy configuration of the servo drive. Automatic commissioning functions and step-bystep wizards allow the parameterisation even without having expert know-how. Thanks to the graphical visualisation of the current operating status of the servo drive also complex correlations can be recognised at a glance.

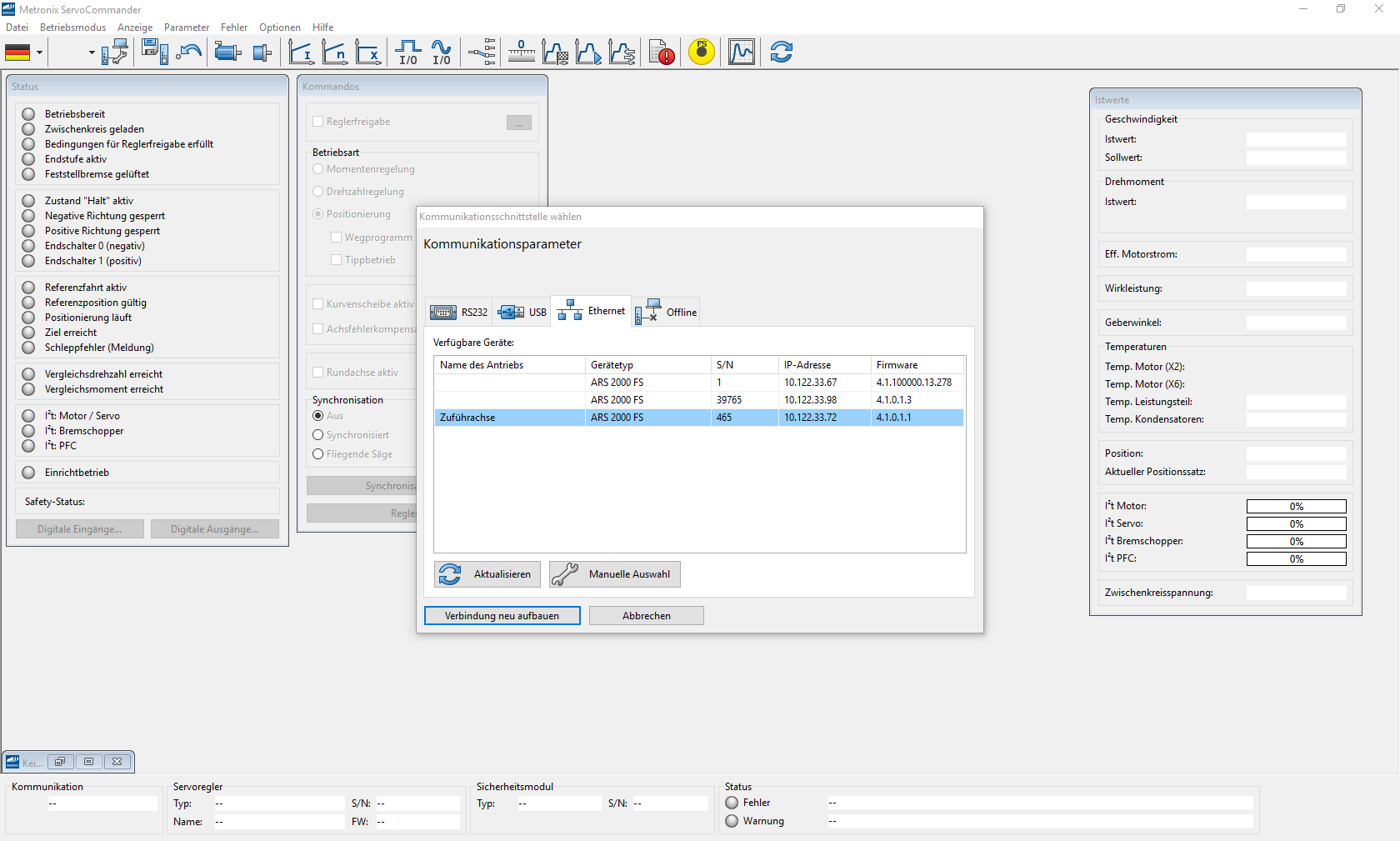

Easy communication

Whether via USB or via Ethernet, the communication with the servo drive is established very quickly: All available devices are clearly listed with their freely selectable name in plain text. Thus, also in a big machine you can keep in view all of your drives.

Graphical visualisation

The menu “controller overview“ shows which servo drive blocks are activated and how they are interconnected. The visualisation is adapted dynamically to the current state of the servo drive.

Special diversity

Servo drive ARS 2000 FS series

The complete ARS 2000 FS series with an output power from 2 A to 40 A is divided into four types. Each servo drive combines highest power density with smallest space.

ARS 2000 FS series

Smart ideas for great projects

To visualise the extreme performance of the ARS 2000 FS servo drive, we have chosen an example from nature: The ant can move objects that exceed its own body weight by a multiple. Just like the compact ARS 2000 FS, that moves for example a machine tool, a packaging machine or a robot precisely, dynamically and controlled. This is an important component for your future and current projects. In this way, together with you, we want to sum up your ideas to big, new projects.