DIS-2-MOUNT

DIS-2-MOUNT

Pure flexibility – for decentralized DRIVE

The DIS-2-MOUNT is very easy to mount on any servo motor by the universal Metronix adapter plate system. This turns a „standard“ servo motor to a decentralized intelligent servo drive. Now, the complete compact electronic unit is housed, where normally the motor terminal box or the motor power and encoder plugs connect the motor to the servo drive.

This saves space in the control cabinet and also expensive shielded cables incl. the installation effort. The DIS-2 is connected to the required power supply of 230V AC or 48 V DC and receives the drive commands directly via fieldbus interface or the I/O level and performs your drive tasks.

DIS-2-CORD

DIS-2-CORD

The robust kind for decentralized DRIVE

The DIS-2-CORD can be adapted very easily to diferent mounting requirements by the robust mounting plate. Due to the high degree of protection, the DIS-2-CORD version adapts to every assembly situation.

Via the EMC-optimized metal circular connectors the required cables (CORD) are connected to the servomotor, power supply and other system components.

Features

Features

DIS-2-MOUNT and CORD

Features

- Power section supply: 48 V DC or 230 V AC (depending on the version)

- Three modes of operation: speed-, torque- and position control

- Compact five-sided closed EMC-optimized metalhousing – protection degree IP54 to IP67 possible

- High control accuracy through high-grade current measurement

- Integrated universal encoder interface for following encoders:

- Resolver

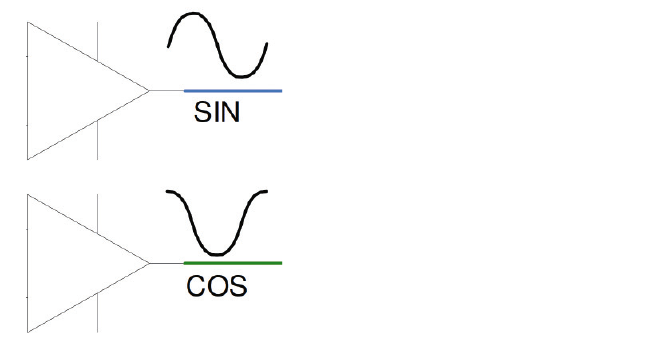

- Analogue hall encoders with SIN-/COS-signals

- High resolution Stegmann incremental encoder, absolute encoder with HIPERFACE®

- Six Step hall encoders

- Incremental encoder with commutation signals

- Connectivity via CANopen, EtherCAT or PROFIBUS to a superordinate PLC

- Integrated position control according to CiA DS402 standard

- Integrated path program for simple automatic processes

- Integrated driver stage for 24 V DC holding brakes

- Integrated brake chopper I²t- observation for the protection of power stage and motor

- Automatic motor identificatio

- Variable DIN / DOUT configuation

- Two variable 12-bit analogue inputs

- Variable 8-bit analogue outputs

- User-friendly parameterization with the PC-Program DIS-2 ServoCommander®

Technology functions

Numerous integrated technology functions make the decentralized DIS-2 servo drive a real all-rounder in drive technology.

Thus, the DIS-2 servo drives not only support numerous motor types and many common position encoders, but also a large number of application tasks can be implemented extremely flexible via simple parameterization of the integrated technology functions. The precise and highly accurate evaluation of external signals in the drive achieves the shortest possible cycle times for your application. The connectivity options of the DIS-2 for communication and encoder interfaces offer a high standard in the decentralized market segment for your drive tasks.

Positioning

Whether linear, jerk-limited or torque-limited: With the integrated positioning control every motion task can be easily realised.

Path program/Chaining

An integrated path program editor with up to 32 rows is available. This allows an interconnection between position sets to solve complex positioning tasks without PLC. Moreover situation-related branches are possible e.g. via digital inputs.

Electronic gear / Synchronization

The position- or speed-synchronous motion of various drives with variable gear ratios can be quickly parameterized via the software assistant.

SAFETY configuation

An additional pop-up menu allows a very comfortable check of the safety status for the application.

Connectivity-Optionen

DIS-2 ready for IoT

CANopen

The CANopen interface is provided according to the CAN in Automation (CiA) protocol DS301 with the application profile DSP402.

EtherCAT

The EtherCAT interface supports the CoE-protocol (CANopen over EtherCAT) by the FPGA Image ESC10. Characteristics: EtherCAT according to IEEE-802.3u (100Base-TX) with 100Mbps (full-duplex).

PROFIBUS

The PROFIBUS-communication is performed according to DP-V0. Functions based on PROFIDRIVE version 3.1 are available for drive technology applications.

Encoder interfaces

Hall sensors (Six Step)

In order to realize cost-sensitive applications, we also support this type of feedback system.

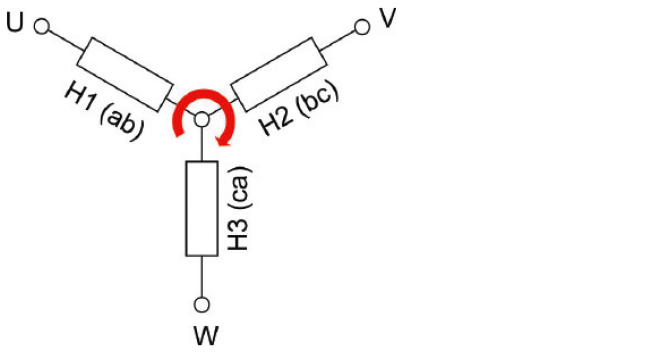

Analogue hall sensors

As another cheap alternative, with good angle accuracy of rotor position, the connection of analogue hall sensors is also possible.

HIPERFACE®

Our decentralized unit supports high resolution Stegmann incremental encoders or absolute encoders with HIPERFACE interface.

Incremental encoders with commutation signals

The standard quadrature evaluation of the A,B,N tracks is also possible. In conjunction with six-step commutation signals, here a high-quality motor control can be guaranteed.

Resolver

The support of the most frequently used encoder system for synchronous servomotors is guaranteed.

Safety

Functions for safe sequences

Short cycle times, maximum accuracy and productivity – this is what machine users demand from a decentralized servo drive in a modern and innovative factory.

Lifting, lowering and positioning: The DIS-2 enables a smooth material flow in modern, efficient conveyor systems with connection to up- and down stream systems. Intelligent, driverless, self-sufficient transport systems that carrying independently piece goods from the loading point to the destination place complement the complex drive tasks. In addition to these high demands on drive performance, the safety of the operating staff must never missed out. Thus, the basic safety features are supported by the DIS-2.

Functions

for safe sequences

STO - Safe Torque Off

Disconnection of the energy supply to the drive according to EN 61800-5-2. This safety function ensures that the drive can no longer be supplied with energy and thus no torque is generated to prevent an unwanted startup.

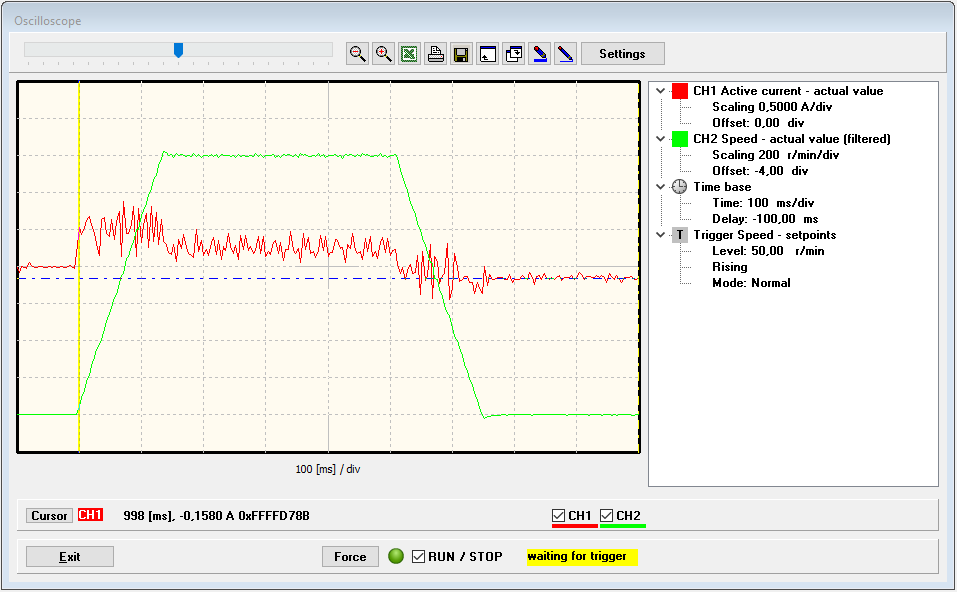

Visualization

The setup software Metronix DIS-2 ServoCommander® allows a quick and easy configuration of the servo drive. Automatic commissioning functions and step-by-step wizards allow the parameterisation even without having expert know-how. Thanks to the graphical visualisation of the current operating status of the servo drive also complex correlations can be recognised at a glance.

Setpoint selection

Via the graphical interface of the DIS-2 ServoCommander®, the required set point selectors can be assigned quickly and easily and selected via drop-down menus. With speed control, the choosen selector can be routed via a ramp generator whose ramps can be parameterized directional in acceleration and braking time. Furthermore, an additional torque limitation can be selected.

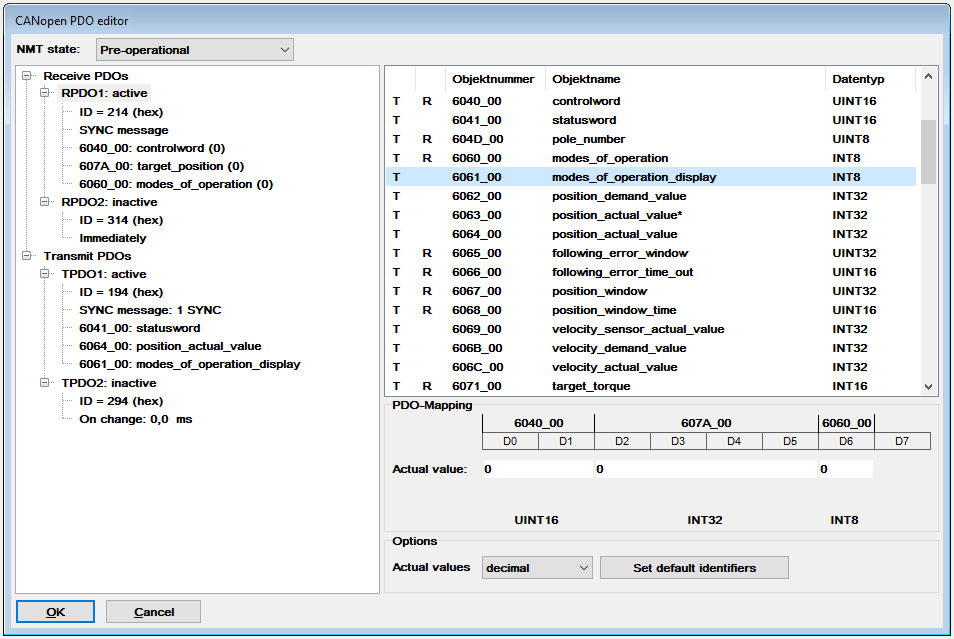

PDO-Editor

The connection to a superordinate control system can be easily performed by „drag and drop" using a comfortable editor. Furthermore the NMT-status of the servo drive can be influenced via drop-down menu at this point.

Technical data

Servo drive DIS-2 series

The DIS-2 platform consists of a 48 V DC and a 230 V AC variant with different specifiations to the connectivity of the motor and the encoder connections.

DIS-2 series

Smart ideas for great projects

To visualize the extreme performance of the DIS-2 servo drive, we have chosen an example from the nature. The ant can move items that exceed a multiple of its own body weight. Just like the decentralized DIS-2 servo drive that moves for example a machine tool, a packaging machine or a robot precisely, dynamically and controlled. This is an important component for your future and current projects. In this way, together with you, we want to sum up your ideas to big, new projects.